Our worldwide success in manufacturing tube mills proves how Creativity, Technology and Reliability are of paramount importance to guarantee the future for plant constructors and tube producers. Thanks to our young and highly professional staff, to whom we are passing on our expertise, MTM guarantees that our Clients can plan their future and make sure it comes true.

Watch full video

Tube forming mills

MTM TUBE MILLS are designed to cover a wide range of solutions for the production of carbon steel, stainless steel and aluminum ERW tubes from 6,0 mm to 259,0 mm Outer Diameter and from 0,2 mm to 10 mm Wall Thickness.

MTM TUBE MILLS are recognized or their high level of automation and precision. They are equipped with advanced in-line control systems that guarantee the constant control of the production parameters as well the quality and reliability of the production.

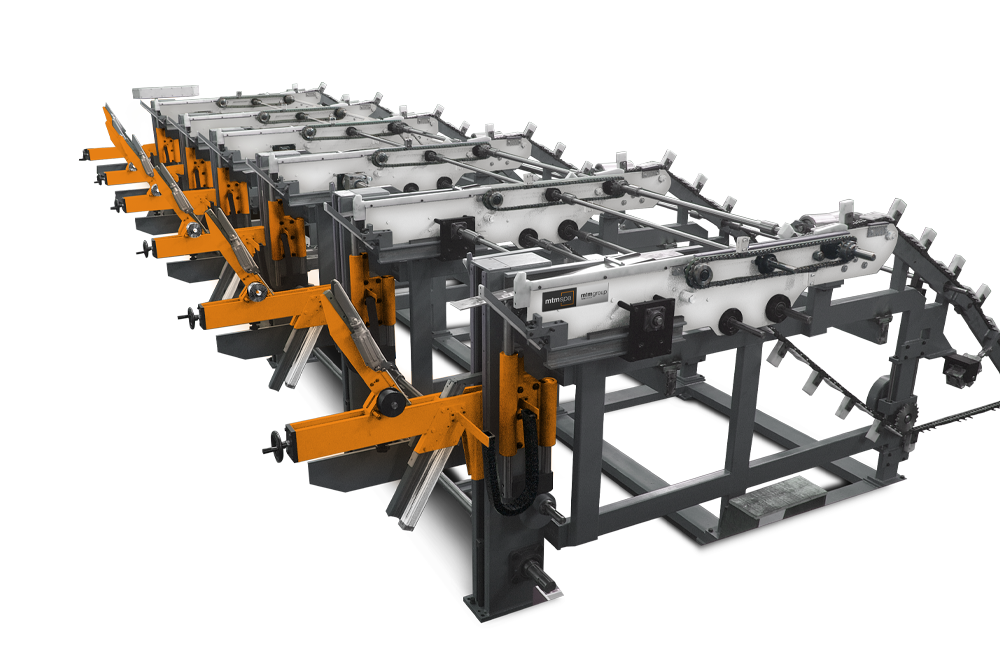

The QC Series offers the tooling quick-change systems, thanks to whom it is possible to perform fast production changes, minimizing the tube mill downtime and guaranteeing high levels of productivity.

Strip entry lines

MTM ENTRY LINES cover the complete range of solutions for coil handling, from coil loading - preparation and unloading, strip joint and traceability, to accumulation and strip feeding into the forming section.

MTM ENTRY LINES fit out the highest level of automation able to guarantee the increasing of plant productivity and eliminating machine downtime.

In accordance with the requested level of automation, the MTM ENTRY LINES are equipped with coil handling conveyor, coil turnstile, coil lifting car, coil upender, double or single decoiler with clamping arms, feeding pinch-roll, strip flattener, strip shear & welder, welding joint annealing system and milling, strip accumulator.

Flying cut off machine

Developed since over 45 years (5 decades) , the MTM CUTOFF MACHINES are designed to perform different type of cutting processes like the cold saw or friction saw, the double-blade orbital or alternate cutting and the flying shear cut.

MTM CUTOFF MACHINES are well-known all around the world for their high precision and performance levels in terms of quality and reliability standards.

The EVO2-CUT software has been developed by Officine MTM in order to allow an easy and intuitive control and set up of the machine. With the WIZARD module, it is possible to set the machine following an icon based wizard, according to the type of pipe to be cut and the blade to be used.

Packing systems

MTM STACKING AND PACKAGING SYSTEMS are recognized for the high quality and reliability, superior design and very accurate manufacture, able to meet any production needs.

MTM STACKING AND PACKAGING SYSTEMS can be customized as front or lateral solution and can come complete with manual or automatic strapping section, weighing and draining section, blowing section, labelling station, data process and storage, production data exchange facility.

On demand, “PRODUTRACK and TECHNOTRACK” software can be supplied to collects all parameters strictly related with the production and traceability.